Nishio Brewing

Miso

Miso used to be made in the family, the true “taste of home”. But with the economic expansion of the Edo period, some kinds of miso became more popular than others and their use spread nationwide. Nishio’s red miso is renowned for keeping its aroma even when it is boiled and for rounding out the taste of other ingredients in cooking.

Misokattsu pork cutlets and Doteni udon noodles simmered in miso have long been favorites of the regional cuisine of Aichi. In recent years, people are becoming more aware of the nutritional value of soy products like miso and it is even attracting attention as a health food around the world now.

Because miso is a fermented food, traditional miso makers are often called jōzō – breweries – in Japanese. There are three of them in Nishio.

Hatoya (Miso Park)

To show how this is done, Mr. Toriyama launched Miso Park ten years ago. Here, you can see, taste and even try hands-on what making miso is all about. The park features a variety of facilities, including a museum, a miso-making experience hall, a restaurant that serves many miso dishes, and a specialty shop for miso and soy sauce, alongside other specialties from Nishio.

| Address | Agatsuma-cho 21 No. 1 |

|---|---|

| tel | 0563-56-7373 |

| web | www.misopark.com |

Suzumiso Jōzōjo

His Bara Kōji (Rose Miso) is a pale, light miso with a short ripening period. It brings out the delicious flavor of the soy-beans and complements seafood well. Although it can be used as an everyday miso, Suzumiso prides itself as the best match for the popular local asari clams.

| Address | Higashitsuzu-cho Gido 61-1 |

|---|---|

| tel | 0563-62-2271 |

| web | suzumiso.jp |

Imai Jōzō

To promote the unique miso his grandfather created, Mr. Imai began sending out his Zoumeshi-ya (“Elephant Fodder”) food truck. A few years later, he opened Zoumeshi-ya as a permanent shop and restaurant and, more recently, his Kissa Zoumeshi cafe. Here you can enjoy a varied menu with miso dishes as well as other delicacies.

| Address | Kira-cho, Yoshida, Kai Kai 113 |

|---|---|

| tel | 0563-32-0048 |

| web | www.imai-miso.com |

Shio

The shioda salt evaporation ponds on the sandy shore in Kira, in the south of Nishio City are mentioned in historical records from the Japanese Middle Ages, the Muromachi period. In the following Edo period, Kira Kozukenosuke Yoshinaka pioneered a new salt production method, making salt ponds lined with channels, called “irihama”. They were used to evaporate sea water down to a higher salt concentration which was then boiled to crystallize the salt.

In those days, aiba-jio salt from Kira was prized because of its low content of the bitter nigari (magnesium chloride) and was traded along the Sanshukaido salt road all the way to Toyoda and Nagano. It was also a key ingredient in Okazaki’s famous Hatcho Miso.

Gradually, more modern salt production methods prevailed and the salt ponds were abolished nationwide in 1971. The last remaining salt maker in Nishio was Aiba Shionosato in Kira. Today, some of their salt ponds have been restored and you can try boiling brine and making your own salt at a museum there.

The Nishio Salt Museum Kira Aibajio no Sato

| Address | 59-1, Shirahama Nitta Miyamae, Kiracho |

|---|---|

| tel | 0563-32-3373 |

| web | www.aibajio.jp |

Experience Salt Making

There are two kinds of events available on request. You can take back the salt that you made after either course.

Shioda Salt Pool Experience

Sprinkle sea-water on the sandy salt ponds in the morning. After drying, the concentrated seawater brine is extracted.

The brine is the boiled down to salt in the afternoon. For school related events, members of Kira Irihama Shioda Preservation Society are available to support the experience.

| Time | 9:30 to 14:30 *Time requirements may vary depending on the group |

|---|---|

| Fee | Adults (ages 16 and above) 500 yen, children 300 yen |

| Remarks | *Please apply at least 10 days in advance, in groups of 10 or more. |

Salt Boiling Experience

Deep seawater taken from the salt fields is boiled down to make salt. About 20g of salt can be made from about 20ml of brine, or from about 100ml of concentrated seawater.

Fresh salt is a semi-liquid sludge, but if it is spread out on kitchen paper and dried for a week or so, it will become pure white and smooth. Kira salt is popular for its delicious sweet notes. It goes well with onigiri rice balls, boiled eggs, and tempura.

| Time required | About 10 minutes |

|---|---|

| Fee | 200 yen per person |

| Remarks | *Please inquire on the day, or make a reservation for groups of ten people or more. Children under the age of eight must be accompanied by one guardian each. |

Saké

What is Nihonshu (Japanese Saké)?

From a legal standpoint nihonshu (Japanese saké) is called seishu (refined saké).

•A filtered product that uses rice, malted rice and water that has been allowed to ferment, as its main ingredients.

•A filtered product that uses rice, malted rice and refined saké (seishu) lees and other ingredients that have been allowed to ferment as stipulated by a cabinet order, as its main ingredients.

After meeting either of these two requirements,

•With an alcohol content of less than 22%

products that meet the above conditions are defined as seishu (refined saké.) Futhermore, the name nihonshu (Japanese saké) is only applied to seishu (refined saké) made within Japan.

The Saké of Aichi

According to records at Mikawa Sakami Shrine, Aichi prefecture’s saké brewing history goes back over a thousand years; since long ago delicious saké has been made using the Yahagi river’s clear stream and good quality rice cultivated in the region’s rich soil.

The popularity of Aichi’s saké was encouraged by Mitsutomo Tokugawa, the second feudal lord (daimyo) of the Owari clan during the Edo period.

In search of a larger market, sales channels were also expanded into Edo (modern day Tokyo) with great success. At that time, because of its high alcohol content Mikawa saké was popularly known as ‘oni o mo yowasu’ (“even gets demons drunk”) and ‘oni koroshi’ (“demon killer.”)

It is thought that the saké of their hometown made the people from the Mikawa and Owari regions living in Edo, including shogunal vassals feel nostalgic.

Finally, it is said that Aichi saké took the saké world by storm and became as popular as Nada’s (Hyogo prefecture) ‘otoko shu’ (“mens’ saké.”)

Today, in this region’s blessed climate and natural features, chief saké brewers and saké breweries still remain, they continue to polish their brewing techniques and strive to improve the quality of their products; and their painstakingly made delicious saké continues to inebriate people throughout Japan still.

Nishio City Brewery Introduction.

Yamazaki Partnership (Trade name: Sonnoh Brewery)

Sonnoh Brewery, which has been dedicated to making saké since its establishment in 1903, uses more than 95% saké rice cultivated in Aichi prefecture, and is committed to using locally grown products.

“When it comes to kinds of saké rice, Yamada Nishiki from Hyogo Prefecture is common, however, we continue to follow our former company president’s belief, as he once said, ‘Let’s make saké with fine quality saké rice cultivated in Aichi prefecture and put its special characteristics to good use.’” This story represents our roots as a local brewery.

This opportunity was the beginning of contract cultivation in the Toba area.

Even today, excellent saké rice is cultivated in this area and this supports Sonnoh Brewery’s saké brewing.

We at Sonnoh Brewery, devote all our time and effort to provide our customers with delicious saké. In-house rice polishing is one of the steps in our saké making process, which is now rare.

Each bottle is labelled by hand while preserving the saké’s taste and aroma at the same time. We aim to improve our saké brewing techniques by also actively working on trial brewing.

“Yume’gin’ga DREAM” was produced after 7 trial productions.

“We want to continue to come out with new products and to continue devoting ourselves to using saké rice cultivated in Aichi prefecture in the future.” Sonnoh Brewery will continue to advance, keeping its traditions as it evolves.

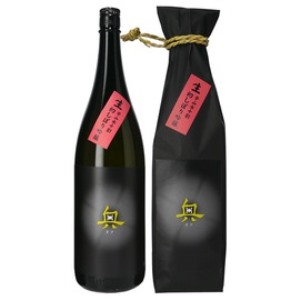

Hiromasa Yamazaki’s recommended fine product of choice

A rich saké, that was developed to compete with the great boom of shochu (a distilled liquor.)

“Niwari-Nibu Oku” uses saké rice that is polished to the extreme and only 22% brown rice (genmai). It is meticulously made with equipment especially designed for the very fine grains of rice used in the “Oku” series’.

Honmirin (literally: true mirin)

There are two theories about the origin of mirin: one is it was brought into Japan from China, and the other is it was born in Japan when shochu such as nerizake and shirozake (both are sake existed in Japan since long ago) was added to sweet sake to prevent it from spoiling and that turned into mirin. It was originally drunk as a sweet sake and became popular among the ordinary people.

In the late Edo period, the foundation of Japanese cuisine was established, and the sweetness of mirin was used as a seasoning for eel sauce and soba (buckwheat noodle) dipping sauce. It was also produced in Mikawa, where brewing was popular.

The manufacturing method was passed on and developed to current “Honmirin (literally: true mirin) ” which is the result of the saccharification and maturation of glutinous rice, koji rice and shochu. The later “Mirin-fu Chomiryo (literally: Mirin-style seasoning) is completely different in terms of ingredients and manufacturing methods.

The main ingredient of Honmirin is glucose, which is rounder and more refined than the sweetness of sugar. The rich flavor soaks into the ingredients and gives them a deep sweet taste. It also has a variety of cooking effects that make food taste amazing, such as glazing and browning, and its alcohol content erase the fishy smell and prevents breakage in cooking.

There are only a handful of Honmirin breweries in Japan, but Mikawa Mirin, which is made from a mixture of rice shochu and kasudori shochu, has a strong aroma. Brewery in Mikawa continues to preserve this tradition to this day.

Mirin brewery in Nishio City.

Aioi Unibio Co., Ltd.

Aioi Unibio Co., Ltd., which began making Mirin in 1872, is a well-established manufacturer that prides itself on its superior fermentation technology.

Mirin is matured for a long period of time with koji to bring out the sweetness. This is why it is important to control the temperature in order for the koji to work most actively.

Amongst the various stages of production, the pressing process is where Aioi Unibio’s unique touch can be seen most clearly. Artisans manually place the moromi inside bags and press it to produce amber-colored mirin. “Our company’s mirin is made using a large amount of rice, and due to moromi’s thickness, it is difficult to mechanize this process.

An old method of pressing is used, where the moromi is manually packed together tightly in a bag before the actual pressing takes place. The process takes an entire day. We continue this traditional process in order to meet the expectations of customers who have a particularly refined sense of taste. Aioi Unibio participates at the local product booths at Nishio City Culture Hall every autumn. “At our booth, we share suggestions for sweets made using mirin.

Mirin is associated with Japanese cooking, but it can actually be used as an ingredient in Western sweets as well. The flavor from the rice’s starch has a sweetness to it that’s even richer than that of sugar.

We want to continue sharing information like this so that more people can learn about appeal of mirin.

“For example, we want to work with local businesses and try our hand at making sauce for broiled unagi. It would be nice if by doing that, our company can become more of a household name.”

Aioi Unibio is always looking to the future, setting its sights on expanding mirin’s hidden potential.

Hiromasa Yamazaki’s recommended fine product of choice

This mirin, which is made using the traditional Mikawa production method also used to make “kasutori shochu” (shochu made from sake lees), really carries the authentic flavor of mirin.

It is made using domestically sourced ingredients, and is the product of a careful 3-year fermentation process. The process is very meticulous, and we do not cut any corners when it comes to ingredients, production and time.